If you are a designer or engineer, aluminum is undoubtedly a high-quality basic material worth considering when designing products related to conductivity. Especially in applications that require precision parts and efficient current conduction, the high conductivity of aluminum makes it an ideal choice. By fully utilizing the electrical characteristics of aluminum, you can design more efficient and reliable products to meet the needs of customers.

Understanding Aluminum

Aluminum is a metal element in the periodic table with the atomic number 13. It is one of the most abundant metals found on Earth, constituting about 8% of the Earth’s crust.

The atomic number 13 signifies the presence of 13 electrons in an aluminum atom, arranged in electron orbitals. In metals, electrical conductivity is largely determined by the availability of free electrons that can move through the material. In aluminum, the three electrons in the outer shell are relatively free to move, facilitating the conduction of electricity.

However, aluminum does not exist in its pure form naturally and must be produced on an industrial scale from its ore—bauxite. It undergoes refining to extract aluminum oxide, which is then subjected to electrolysis to obtain pure aluminum metal.

Can Aluminum Conduct Electricity?

Indeed, aluminum is among the top materials for electrical conductivity, second only to pure copper. Pure aluminum boasts a remarkable conductivity of 37.7 MS/m, making it highly effective for various electrical uses.

To understand aluminum’s efficiency as a conductor, it’s often compared to copper, which is the leading conductor after silver. However, due to silver’s high cost, it is not feasible for extensive industrial applications. This is where aluminum becomes advantageous as a cost-efficient alternative.

The International Annealed Copper Standard (IACS) provides a basis for comparing electrical conductivity across materials. Aluminum stands at 61% IACS, indicating it has 61% of the conductivity of copper. While this is less than copper, it is still highly effective, particularly in applications where weight and cost are crucial factors.

In practice, aluminum’s conductivity is so reliable that most power transmission lines utilize aluminum. This means the electricity reaching your home likely travels through aluminum conductors. Moreover, aluminum’s resistance to corrosion enhances its durability, making it a long-lasting choice for electrical infrastructure.

How Does Aluminum Conduct Electricity?

The exceptional conductivity of aluminum arises from its atomic makeup and the way its atoms bond. Aluminum atoms consist of a nucleus made up of protons and neutrons, surrounded by electrons in specific orbitals. Aluminum has 13 protons and 13 electrons, which is why it is designated as element 13 on the periodic table. These electrons are distributed across different energy levels or shells, with three electrons in the outermost shell.

These outermost electrons, known as valence electrons, are not tightly bound to the nucleus, allowing them to move relatively freely. When aluminum atoms come together to form a solid, these free-moving electrons create what is often referred to as a “sea of electrons.” This sea of electrons is crucial for the material’s ability to conduct electricity.

The Concept of Electric Current and Charge

To understand the electrical conductivity of aluminum, it is essential to grasp the concept of electric current. Electric current is the flow of electric charge, which can be carried by ions or electrons. In metals like aluminum, the charge carriers are the free electrons in the “electron sea.”

When a voltage is applied across a piece of aluminum, it creates an electric field that causes these free electrons to drift towards the positive terminal. This drift constitutes an electric current. The ease with which these electrons can move through the aluminum is a measure of its electrical conductivity.

Aluminum’s Role in Conducting Electricity

The ability of aluminum to conduct electricity efficiently is due to the mobility of its free electrons. These electrons are not tightly held by the atomic nuclei, allowing them to respond quickly to an electric field. This movement of electrons enables aluminum to conduct electric current effectively.

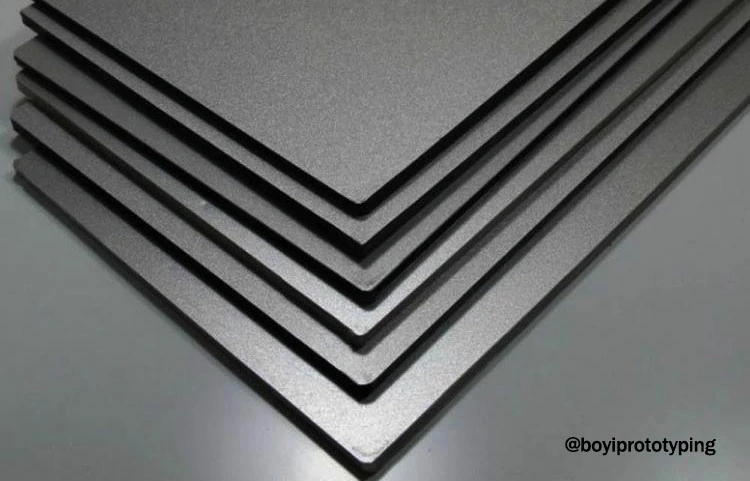

Raw Aluminum

Pure aluminum exhibits moderate electrical conductivity compared to other metals like copper and silver. It has a conductivity of approximately 37.7 million siemens per meter (MS/m), which is lower than that of copper (58 MS/m) but still sufficient for many electrical applications.

The following table lists the electrical conductivity of other aluminum alloys:

| Type/Alloy | Electrical Conductivity (MS/m, 20°C) | Remarks |

|---|---|---|

| Aluminum-Copper Alloys (2XXX Series) | 30.0-40.0 | Electrical conductivity varies depending on copper content, suitable for some special electrical applications |

| Aluminum-Manganese Alloys (3XXX Series) | 30.0-35.0 | Good workability and corrosion resistance, moderate electrical conductivity |

| Aluminum-Silicon Alloys (4XXX Series) | 25.0-30.0 | Primarily used for casting, lower electrical conductivity |

| Aluminum-Magnesium Alloys (5XXX Series) | 30.0-35.0 | Good corrosion resistance, moderate electrical conductivity |

| Aluminum-Magnesium-Silicon Alloys (6XXX Series) | 32.0-37.0 | Used in automotive and building applications, higher electrical conductivity |

| Aluminum-Zinc Alloys (7XXX Series) | 20.0-25.0 | Primarily used in aerospace, lower electrical conductivity |

| Other Aluminum Alloys (8XXX Series) | 25.0-35.0 | Specific applications, electrical conductivity varies depending on alloy composition |

Anodized Aluminum

Anodizing is an electrochemical process that enhances the surface properties of aluminum. It involves creating a controlled oxide layer on the metal’s surface, which can improve corrosion resistance, durability, and even aesthetics. However, anodization affects the electrical conductivity of aluminum.

Initially, during anodization, the surface of aluminum develops a porous oxide layer, which is non-conductive. This layer can be further treated or sealed to achieve desired properties. While pure anodized aluminum has a significantly lower electrical conductivity than raw aluminum due to this insulating oxide layer, the exact conductivity depends on the thickness and type of anodization.

The conductivity of anodized aluminum oxide is much lower than that of pure aluminum or aluminum alloys that have not been anodized. The specific conductivity value depends on the thickness and density of the oxide film, but is usually much lower than the 37.7 MS/m of pure aluminum (at 20 ° C).

Electrical Conductivity of Anodized Variants:

- Type II Anodization: This type of anodization results in a thinner oxide layer (typically 1 to 25 microns thick) compared to Type III anodization. The oxide layer is porous and can be dyed or sealed, affecting its conductivity.

- Type III Anodization (Hard Anodizing): This process creates a thicker and denser oxide layer (typically 25 to 150 microns thick). The resulting layer is more wear-resistant and provides better insulation, significantly reducing the electrical conductivity of the aluminum.

Will Aluminum Surface Finishing Affect Electrical Conductivity?

During the anodizing process, the formed oxide layer is very thin and non-conductive, which requires aluminum to consider the loss of conductivity in electronic applications. After surface treatment such as anodizing or powder spraying, the conductivity of different types of aluminum will decrease. Anodizing can produce oxide layers with different thicknesses and properties, thereby affecting the electrical conductivity of the final product. In contrast, although powder spraying does not form a completely isolated oxide layer on the aluminum surface, it still has a certain degree of impact on the conductivity.

Untreated or lightly treated aluminum is usually preferred in electronic devices to ensure good electrical conductivity. In external applications that require corrosion resistance and environmental protection, anodizing or powder spraying is more preferred to enhance the durability and appearance of aluminum.

How to Measure Conductivity of Aluminum?

To measure the conductivity of aluminum, first, a known current is passed through an aluminum sample. Next, probes are used to measure the voltage drop across the sample. With these measurements and the sample’s dimensions, the conductivity can be calculated using the following formula:

Conductivity (σ) = (Current (I) × Length (L)) / (Voltage Drop (V) × Cross-sectional Area (A))

Where σ is the conductivity in Siemens per meter (S/m), I is the current in amperes (A), L is the length of the sample in meters (m), V is the voltage drop in volts (V), and A is the cross-sectional area of the sample in square meters (m²).

Wide Applications of Aluminum as an Electrical Conductor

Aluminum has gained widespread application as an electrical conductor, particularly in the power industry, where it has demonstrated its unique advantages. On high-voltage power poles, engineers and workers frequently encounter aluminum conductors due to its notable benefits over other materials.

In recent years, aluminum has also gained popularity in residential, aircraft, building, and household appliance applications. For instance, aluminum wires are often used to replace traditional copper wires in home electrical circuits, reducing the weight and cost of wiring. In aircraft manufacturing, aluminum conductors’ lightweight nature makes them ideal for connecting various electrical circuits and systems. In buildings, aluminum busbars are used to distribute power to different circuits and floors, meeting the electrical needs of the structure.

Comparing Aluminum Electricity Conductivity to Other Metals

Here’s a comparative table of electrical conductivity for aluminum and some other commonly used metals:

| Metal | Electrical Conductivity (MS/m) |

|---|---|

| Aluminum | 37.7 |

| Copper | 58.0 |

| Silver | 63.0 |

| Gold | 45.0 |

| Brass | 15.9 – 28.0 |

| Iron (pure) | 10.0 |

| Steel (low carbon) | 6.99 |

| Zinc (pure) | 16.6 |

| Nickel (pure) | 14.0 |

Note: Electrical conductivity is typically measured in units of million siemens per meter (MS/m) or mega siemens per meter (MS/m).

This table shows that aluminum has a good conductivity, though it is lower than that of copper and silver, which are known for their excellent conductivity. However, aluminum’s lower cost and lighter weight often make it a preferred choice for various electrical applications where high conductivity is not the sole consideration.

Why Copper is More Conductive than Aluminum?

Copper remains the primary choice for electrical conductors for several reasons, including its superior ductility, appealing golden-brown finish, and enhanced strength and hardness. However, its most significant advantage is its superior electrical conductivity compared to aluminum. This superiority is primarily due to copper’s lower resistance to electric current.

Understanding Electrical Resistance and Conductivity

Electrical resistance measures how much a material opposes the flow of electric current. Materials with high resistance, such as plastic or rubber, are known as insulators. While all materials have some resistance, metals typically exhibit very low resistance, making them good conductors of electricity.

Resistance depends on two factors: the dimensions of the conductor and a material-specific property known as resistivity. Resistivity is an intrinsic property that quantifies how strongly a given material opposes the flow of electric current. When comparing copper and aluminum conductors of equal length and cross-sectional area, copper demonstrates higher conductivity due to its lower resistivity.

Resistivity of Copper vs. Aluminum

The resistivity of copper is lower than that of aluminum. Specifically, copper has a resistivity of approximately 1.68 x 10^-8 ohm-meters, while aluminum has a resistivity of about 2.82 x 10^-8 ohm-meters. This lower resistivity in copper means that it offers less opposition to the flow of electric current, allowing electrons to move more freely and efficiently through the material.

Electron Behavior and Phonon Collisions

On a microscopic level, copper’s superior conductivity is also due to the behavior of its free electrons. Free electrons in copper are less likely to encounter a phenomenon known as phonon collision. Phonon collisions occur when vibrating atoms within a material create mechanical energy that interferes with the movement of electrons. These collisions increase the material’s resistance to electric current.

Despite aluminum having a higher concentration of free electrons than copper, these electrons are more prone to phonon collisions. This increased scattering of free electrons in aluminum contributes to higher resistance and, consequently, lower conductivity compared to copper.

Experimental Evidence and Practical Implications

Experimental data confirms that copper is a better conductor than aluminum. The free electrons in copper experience fewer phonon collisions, enabling a more efficient flow of electric current. In contrast, the free electrons in aluminum encounter more interruptions, leading to increased resistance.

Practical Applications and Advantages of Copper

Due to its lower resistivity and fewer phonon collisions, copper is the preferred material for many electrical applications. Its high conductivity makes it ideal for wiring in homes, buildings, and electronic devices, where efficient and reliable electrical performance is critical. Additionally, copper’s ductility allows it to be easily formed into wires and cables, enhancing its practicality in various applications.

Conclusion

In conclusion, while raw aluminum possesses moderate electrical conductivity suitable for many applications, anodization alters its surface properties, including conductivity. Understanding the conductivity of aluminum, whether raw or anodized, is crucial for leveraging its properties effectively across industries where both electrical performance and material durability are critical.

BOYI, Your professional aluminum parts processing service provider. Whether you need milling or turning, we can provide you with high-quality and accurate machining solutions.

At BOYI, we have advanced processing equipment and an experienced technical team that can handle various complex aluminum alloy processing needs. Whether it is small batch customization or large-scale production, we are committed to providing customers with fast response and satisfactory services.

Let’s Start A New Project Today

Our engineers will contact you within 2 hours.

FAQ

Aluminum electrical cables are primarily made of aluminum alloys, including pure Electrical Conductor grade aluminum, alloy 6201, and aluminum 1350. Some cables, like ACSR and ACAR, combine aluminum alloys with steel or aluminum alloy cores for added strength. AAC is often used in urban distribution, while AAAC is noted for its corrosion resistance. ACSR is popular for transmission and distribution due to its steel core, and ACAR offers improved electrical and mechanical properties but is more costly.

Aluminum is widely used in electronics and electrical products due to its lightweight, conductivity, and cost-effectiveness. It’s commonly found in overhead transmission lines, electrical components like connectors and casings, and heatsinks for efficient heat dissipation.

Aluminum grades, ranging from the 1000 series to the 8000 series, vary in their electrical conductivity due to differences in alloy composition and treatments. The purest form, 1000 series (EC-grade aluminum), achieves approximately 61% IACS conductivity, ideal for applications requiring high electrical and thermal conductivity. Other grades like AA-8006 and AA-8011 also exhibit good conductivity, suitable for specific applications such as aluminum wiring and construction.

Yes, aluminium is a good electrical conductor. While it is not as conductive as silver or gold, which are too expensive for regular use, aluminium is the second most conductive metal suitable for practical and industrial applications, next to copper. Its lightweight nature is a significant advantage, especially in industries where weight reduction is crucial, such as aerospace.

Yes, aluminium finishings can indeed impact electrical conductivity. Generally, untreated aluminium offers better conductivity compared to aluminium with coatings or surface treatments like anodizing, which create an oxide layer that increases electrical resistance. Other coatings like paint or enamel can also affect conductivity.

Conductivity is important in aluminium because it affects power transmission efficiency, wiring applications, industrial uses, electronics, heat dissipation, and cost-effectiveness due to its lightweight nature. Efficient conductivity ensures less energy loss, improved performance, and safer operations.

Catalog: Materials Guide

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.