Injection molding is a widely used manufacturing process for producing parts in large volumes. To ensure the success of injection molding, various components, such as mold lifters, play a crucial role. Mold lifters are mechanisms used to create undercuts or complex features in molded parts by enabling the removal of the part from the mold.

This guide aims to provide a comprehensive overview of the design considerations and principles behind injection mold lifters.

Understanding Injection Mold Lifters

Injection mold lifters, also known as ejectors or ejector pins, are essential components in the mold-opening phase of the injection molding cycle.

Injection mold lifters are mechanical devices incorporated into the mold to facilitate the ejection of parts with complex geometries. They are essential for molds containing features such as holes, threads, or undercuts that cannot be removed straight out of the mold. Lifters work by creating a vertical or angular movement to release the part from the mold cavity. For a more detailed introduction, please read the following information.

Injection Molding Lifters Working Principle

Injection molding lifters consist of a lifting mechanism, often in the form of a blade or pin, which is mounted on an ejector plate. The ejector plate is attached to a hydraulic or pneumatic system that controls its movement. When the mold opens, the ejector plate and attached lifter begin to move upward, pushing the plastic part out of the mold cavity.

The lifter enters the mold cavity through a precisely machined hole and pushes the part upward and at an angle. The angle of the lifter is designed to match the internal undercut of the part, ensuring that the part is evenly and smoothly ejected. To prevent the part from remaining stuck on the lifter, an ejector pin may be used to provide an additional pushing force.

Injection Molding Lifters Types

Injection molding lifters can be classified into two main types: integral and non-integral.

Integral Lifters

Integral lifters are a single unit that combines the lifting mechanism and mounting hardware.They are typically used for molding smaller parts where precision and compact design are critical. Integral lifters offer a simpler installation process and reduced maintenance requirements.

Non-Integral Lifters

Non-integral lifters consist of two separate units: the lifting mechanism and a separate mounting assembly. They are commonly used for injection molding larger parts that require higher ejection forces. Non-integral lifters offer more flexibility in design and can be customized to fit specific mold configurations.

Injection Mold Lifter Design Standards

In order to ensure the correct operation of the injection mold lifter design, the following key standards and specifications must be met:

- Whenever feasible, it is recommended to utilize the Progressive Standard Unilifter Round Core Blade Undercut Release System, integrating either a standard Progressive head design or a customized head detail securely attached to the rod section of the assembly using a precision-rolled dowel. Strict adherence to all Progressive Application Protocols is essential.

- The lifter head design must incorporate a shut-off angle of at least 3 degrees to ensure effective sealing and prevent leakage. This angle is crucial for maintaining optimal mold performance and part quality.

- Without special engineering considerations, the maximum permissible angle for lifter travel is typically limited to 11 degrees. This limitation ensures smooth and controlled movement of the lifter, minimizing wear and tear on the mold components.

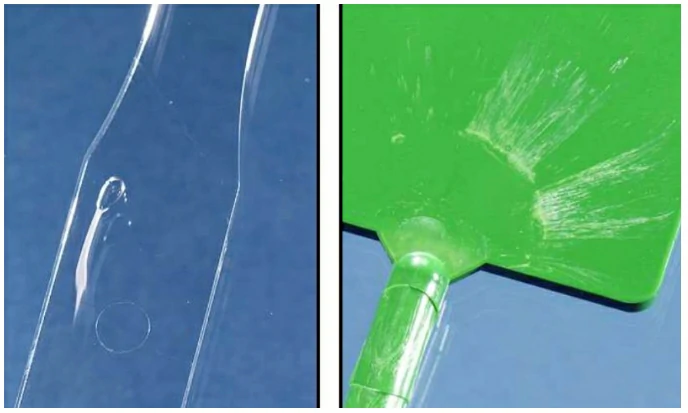

- A pad with a thickness ranging from 0.003” to 0.005” should be implemented on top of the lifter to minimize friction and prevent the molded part from getting “dragged” during the ejection process. This pad reduces the chances of surface scratches or damage to the part.

- Many molded parts tend to adhere to the lifters, remaining attached to the details formed by the lifters, preventing the parts from falling freely. In scenarios where there are no features or sidewalls to retain the parts, it is advisable to consider extending ejector pins into the wall section. Additionally, incorporating “gripper” details on the face of the ejectors can further enhance part retention. It is important to note that when implementing this design, the ejector pins must be keyed to ensure stability and prevent movement during operation. Molded guide posts are also a viable option, but their use should be approved by the Customer based on specific application requirements.

Injection Mold Lifter Material Considerations

Since lifters enter and exit the mold cavity repeatedly, they are subjected to high wear and abrasion. Therefore, hardened steel is often used as the material for lifters due to its excellent abrasion resistance and durability. However, hardened steel is relatively expensive and requires precision machining to ensure accurate fitment and smooth operation.

Injection Mold Lifter vs Slide

Both sliders and lifters are integral parts of the mold and are designed to operate automatically when the mold opens.

Injection mold slides, commonly referred to as sliders, are designed to address external undercuts, recesses, or projections on the outer surfaces of a part. These features prevent the part from being ejected directly from the mold cavity, necessitating the use of a slide mechanism. Slides move horizontally along predefined tracks within the mold, typically actuated by a cam or wedge system. This allows the slide to clear the obstruction, enabling the part to be safely ejected.

On the other hand, lifters are utilized to release internal undercuts, recesses, or projections that are present on the inner surfaces of a part. Lifters are vertically actuated devices that are often integrated into the mold core. As the mold opens, the lifters rise, clearing the internal obstruction and allowing the part to be removed.

Start Your Injection Molding Project with BOYI

At BOYI, we have a team of experienced injection molding experts ready to guide you through every step of your project. Regardless of the size of your order, BOYI provides customized services designed to optimize workflows, reduce injection molding costs, and shorten project timelines. Whether your injection mold requires sliders or lifters, BOYI can meet all your complex and specialized needs.

Choose BOYI for efficient, reliable, and professional injection molding services. If you have any questions or needs regarding your injection molding project, feel free to contact us at any time.

Let’s Start A New Project Today

Conclusion

Designing injection mold lifters requires careful consideration of various factors, including part geometry, material selection, mechanism type, and integration with the mold. By following a systematic design process and leveraging advanced simulation tools, engineers can develop robust lifter solutions that ensure the successful production of complex molded parts.

FAQ

The angle of a lifter is determined based on the geometry of the undercut and the movement required to release it. Careful calculation and simulation are used to ensure the angle provides smooth motion without excessive friction or wear.

The common types of lifters include straight lifters, angle lifters, side lifters, and collapsible core lifters. Each type is designed for specific undercut scenarios and part geometries.

Advanced CAD/CAM software allows for accurate design and simulation of lifter mechanisms. It helps in visualizing the lifter’s movement, optimizing angles, and ensuring all components fit together correctly, reducing the risk of design errors and improving overall efficiency.

Catalog: Injection Molding Guide

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.