The characteristic of clear plastic injection molding lies in its inability to conceal any flaws, which demands higher skill and precision in both design and manufacturing processes compared to materials that may mask imperfect designs. Therefore, clear plastic imposes higher requirements on how we manufacture parts. Every aspect, from raw materials to equipment, molds, and the planning and preparation of molding processes, must be meticulously executed.

BOYI boasts an experienced and highly skilled team, offering support from part design to prototype design and production with expertise and knowledge. Request an injection molding quote now – we manufacture complex clear plastic parts with astonishing speed!

Materials Options Used To Make Clear Plastic Molding

Unlike opaque injection molding, clear plastic injection molding demands meticulous attention to detail and rigorous manufacturing controls. Selecting the most suitable transparent plastic for your requirements is paramount.

Various materials offer distinct advantages in transparent plastic injection molding. Here’s an list of the quality of our transparent plastic materials.

Acrylic

Acrylic (PMMA) is a versatile material suitable for injection molding, capable of producing both crystal-clear and colored plastic products. Its non-toxic nature, scratch resistance, and UV resistance make it highly sought after for outdoor equipment applications. Its versatility extends to various applications, including light fixtures, retail displays, reflectors, and colored lenses.

However, acrylic’s rigidity and brittleness mean it may not be suitable for products requiring high pressure resistance. Additionally, its tendency to absorb moisture necessitates drying, potentially slowing down the manufacturing process and causing complications for end-users.

Nylon

Nylon (PA), also known by its chemical symbol polyamide, is renowned for its robustness and adaptability, making it a favored material for various applications. Nylon quick-release buckles exemplify its versatility, providing durability and reliability. Commonly used in mechanical components such as bushings, gears, and bearings, nylon showcases its strength and resilience. In automotive applications, nylon offers significant advantages, including weight reduction and lower injection molding costs compared to metal alternatives, making it a preferred choice for manufacturers seeking cost-effective solutions without compromising on performance.

Polycarbonate

Polycarbonate (PC) is a clear plastic injection molding alternative, albeit more costly than acrylic or HDPE. It shares similar transparency and UV resistance with acrylic but boasts greater resilience against extreme temperatures. Safety goggles, helmets, shields, heavy-duty containers, and safety windows exemplify the products made from this plastic, designed to endure high-stress environments.

Optical Silicone Rubber

Optical Silicone Rubber (OLSR) represents an advanced material choice, preferred over polycarbonate (PC) or acrylic (PMMA) for lighting and clear optical parts due to several key properties. While all materials inherently reduce light transmission, OLSR stands out by enabling up to 94% light transmission, enhancing clarity in products requiring clear PC or PMMA components.

Another significant advantage of OLSR is its non-yellowing characteristic. Unlike thermoplastics lacking UV resistance additives, which may yellow and degrade over time with prolonged exposure to light and sunlight, OLSR remains non-yellowing. This attribute makes it particularly suitable for outdoor fixtures subjected to harsh environmental conditions.

Thermoplastic Polyurethane

Thermoplastic Polyurethane (TPU) boasts exceptional tensile and tear strength while maintaining a soft and elastic nature. This unique combination of properties makes TPU an ideal choice for objects requiring a firm grip. However, it’s worth noting that TPU tends to be more expensive compared to other resins. Consequently, it is commonly utilized for manufacturing components that necessitate rubber-like elasticity.

Thermoplastic Rubber

Thermoplastic Rubber (TPR) is a blend of plastic and rubber known for its ease of use in the injection molding process. TPR finds applications in a wide range of products, including fluid dispensers, flexible hoses, catheters, and other components that come into contact with various liquids, including acids.

Most Popular Materials for Injection Molding

The most popular materials we use to produce clear plastic injection molded parts include:

- Acrylic

- Polycarbonate

- PETG

- PP

- HDPE

However, it’s essential to note that popularity alone shouldn’t dictate your material choice for your part. Each project is unique, and it’s crucial to consider factors such as application requirements, performance specifications, and environmental conditions. If you’re unsure about the best approach, one of our application engineers at BOYI can provide guidance tailored to your specific needs.

Design Tips for Clear Plastic Molding Parts

In order to prevent poor reflux or uneven cooling that may cause poor plastic molding, surface injection molding defects, and deterioration. Therefore, in mold design, BOYI provides some design reminders here:

- The wall thickness should be as uniform as possible, and the demolding angle should be sufficiently large;

- The transition part should be gradual. Smooth transition to prevent sharp corners. Sharp edges, especially PC products, must not have any gaps;

- Gate. The runner should be as wide and short as possible, and the gate position should be set according to the contraction and condensation process. If necessary, a cold material well should be added;

- The surface of the mold should be smooth and have a low roughness (preferably less than 0.8);

- Exhaust hole. The groove must be sufficient to timely discharge air and gas from the melt;

- Except for PET, the wall thickness should not be too thin, generally not less than 1 mm.

Our website offers a wealth of design tips and resources to assist you in optimizing your molding process for clear plastic parts. Be sure to explore our website for valuable insights and guidance on achieving high-quality results in clear plastic injection molding.

Choose BOYI Molding Services for Clear Plastic Parts

Are you looking for the best partner in clear plastic molding? Our service network spans the globe, ensuring that no matter where you are, our professional team will work closely with you to meet your expectations for every product.

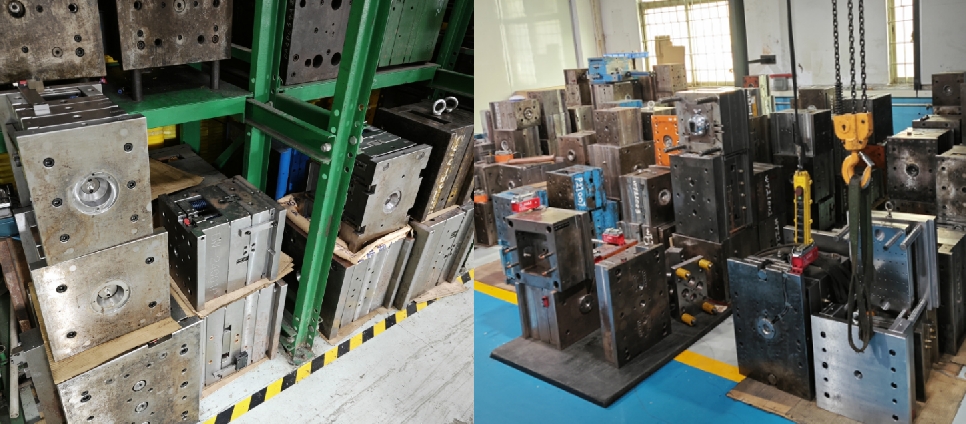

BOYI boasts advanced molding equipment and a specialized technical team. From material selection to the molding process, each step is meticulously controlled to ensure the quality and precision of our products. We understand that every detail impacts the product’s quality, and our dedication has built BOYI’s reputation.

Don’t wait any longer. Contact BOYI now to request a quote and discover how our clear plastic molding services can bring unparalleled value to your next project.

Experience BOYI Injection Molding Services

All uploads are secure and confidential.

Conclusion

Mastering advanced manufacturing techniques and processes, along with possessing extensive design and manufacturing experience, is essential for producing high-quality, clear molded parts. This expertise allows for the creation of parts that add more possibilities and value to products.

FAQ

Yes, BOYI offers custom services and can design and manufacture clear plastic molding parts in specific shapes according to customer requirements. We have a professional design team and advanced molding equipment to meet the personalized needs of our clients.

The delivery time depends on the complexity of the product and the order quantity. Generally, we will communicate with the customer to determine the delivery time. We have an efficient production process and a professional team, and we strive to ensure timely delivery.

Catalog: Injection Molding Guide

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.